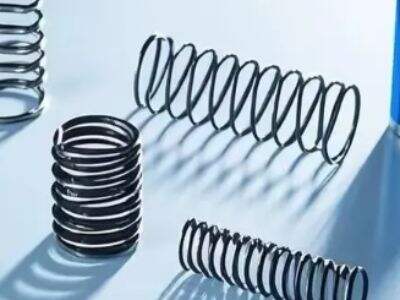

Compression springs are components crucial to enabling machines to operate smoothly by storing and releasing energy as required. If you compare these with the springs, you’ll find out that their ends are made in a different manner. This variance can affect how the spring fits into a machine or operates. At Lisheng, There are various of springs in compression, such as the conventional constant pitch spring, conical spring and the shape at both porcine and rodent ends. NIt’s important to know the difference between closed and ground ends when choosing a compressed spring for your project or machine. It all sounds so basic, but these little details add up to some real performance and safety advantages

Compression Spring End Types: Closed and Ground

Closed ends and grounded ends are two methods of ending a compression spring, although one is not the same as another. Closed end refers to the last coil of a helical spring, which is bent so that it touches the preceding coil. This gives the end a clean finish and prevents the spring from catching on any other components. But the finish may still feel rough or uneven. In contrast, a ground end refers to where the end is ground flat following closure of the coil. Grinding removes any unevenness and finishes the end totally flat and smooth. This enables the spring to still stand up without wobbling on a flat surface. If a spring is required to push against a flat plate or surface, for instance, then the ground end is better because it distributes the force more evenly. Closed ends are okay too unless they tip a spring or shorten its service life on some machines. With Lisheng, we have a lot of customers who use closed ends if they are looking for a basic spring that also keep costs down and fits nicely into a compact design. When you need consistency and excellent force at the contact point, choose our ground end springs. In certain cases springs with closed ends may be noisy and cause additional wear due to asperity contact. Taper grinding corrects this, but it also adds a manufacturing step, so ground ends typically cost a little more. There’s always the made-in-Taiwan or -China ratio to keep in mind. Understanding when to use each is key and it’s part of why working with people like Lisheng means you’ll get the right spring every single time

Where to Turn for the Best Compression Springs with Closed vs. Ground Ends, For Bulk Purchase

There are good compression springs out and about, with closed or ground ends, but they can be difficult to find. Quality means a great deal, though; springs that break or fail lead to delays and additional costs. Lisheng features Original Equipment Manufacturer (OEM) quality springs. We make with strong materials and follow strict rules in production. If you are in need of a lot of springs for a factory or large project, it might make sense to buy them in bulk from a reputable supplier and save money and hassle. Our Lisheng team knows just how know them. How to help you to choose the right springs for your particular application. For instance: if you need springs for heavy machines that exert a lot of force, often, then ground ends might be better. For lighter purposes, closed ends might be all that’s required. We also provide guidance on the sizes and materials that correspond to your machine, as well as how these springs will perform in different machines. When you order from Lisheng, you get spring designs that are made with precision and care: All orders are passed through our quality control and packaged to arrive in perfect shape, on the scheduled date. And, our customer service helps answer any questions you have about springs and using them. We are able to process bulk orders because we have the tools and talent needed to make high quantity products without compromising the integrity of anything that comes off our machines. Selecting Lisheng means you can rely on your machine tools to grow reliably. This is why so many companies rely on us for compression springs that feature closed or ground ends. We care that you find what you are looking for quickly and at a fair price

Popular Problems in the selection of Closed End and Ground end Compression Springs on Bulk Orders

When you are trying to purchase a lot of compression springs at one time, like in big order, then it is important to understand the difference between closed end and ground end springs. Both of these kinds look a little bit different and work in slightly different ways. Closed end springs are closed on the last coil, the tip bends so if broke it will cause a further rounding of this coil holding it in place. This will leave the ends flat, but not smooth. Ground end springs go a step further and grind the ends flat after closing them. This grinding will make the ends nice and smooth, which makes them nice and flat on flat surfaces

One of the common mistakes when purchasing springs in large quantities is not giving thought to how the ends are going to effect the machine or mechanism that the spring will be place into. Closed end springs can be less expensive and easier to make, but if the spring has to fit close or move through a hole snugly, the not-so-smooth edge of the closed end can pose problems. Inspecting and swapping out the springs can also slow down production, something iPhone factories famously won’t tolerate. If a spring with sealed ends is used over a surface that must be ultra flat, for instance, the spring might wobble or wear faster. Any that are ground at the ends are a little more expensive, but they run better and true especially if used in an engine or machine where everything is machined accurately

Another challenge is how to line up those springs, or how they nest or stack if a product incorporates multiple. Ingersoll closed end springs are sometimes not as true on the bottom of spring (ground) that is wrapped by end edge and customers experience uneven pressure or noise. It’s easy to overlook these minor details when you’re buying in bulk, but they can lead to significant problems down the road. Lisheng assists customers by walking them through these distinctions, so they can select the variety that’s best for their needs. Choosing the incorrect end can result in extra repairs or unhappy customers specifically when numerous springs are incorporated into one product

To ensure trouble-free use, it’s also key to consider what type of application the spring will be used in and how smooth any ends of the springs need to be. Lisheng provides advice and quality checks to ensure bulk orders meet customers’ requirements. This saves buyers time and money by not having to search for the correct spring end. Knowing these common causes helps everyone get better outcomes with compression springs

Where Closed End Compression Springs Outperform With Ground Ends Heavy Duty Application

Closed end compression spaces are also a really good choice for heavy work, but they work differently than ground end springs. When you need to do heavy lifting, and we mean springs, the kind that pushes or pulls with a force – closed end coil springs are capable enough to make it happen without getting extra grinding done on top. This is because the closed end design often means that the last coil of spring actually becomes stronger, and able to withstand heavy forces without bending as readily. This is significant in machines or tools that are worked hard and require parts that won’t break or deform easily

A big advantage with closed end springs in heavy work is, frequently they save the cost of manufacture. Manufacturers like Lisheng can make the filters cheaply and more quickly, because they don’t require an additional grinding step. That is, companies that want a bunch of springs for large machines or powerful tools might be able to get away with saving some money without giving up strength. Construction tools or big machines, for instance, closed end springs are a good choice to meet the requirements of enough sturdiness for a work while without perfectly flat ends

Closed end springs usually last a long time in these tough conditions also since their shape assists in spreading out the pressure more evenly. The closed coil end helps keep the spring in place and prevents it from twisting after hard pushes. This is useful for heavy machinery that tends to shake or shift. And although ground end springs have a smoother surface, sometimes the grinding operation can make the spring slightly weaker at some point in its stock. So for the most aggressive, hard-use situations, closed ends can in fact be safer and more durable

Lisheng knows not every heavy duty application requires the highest finish. Occasionally, strength and price trump all. Therefore, for large orders of springs supplying heavy and durable tools or machines, a closed end spring is generally the best choice. They offer the power and durability you need at no extra cost, making them a smart choice for many buyers. Knowing where closed end springs are best means people can choose the right spring for their heavy-duty work

How End Type Affects Durability and Quality of Compression Springs in Wholesale Markets

The type of end on a compression spring, whether closed or ground often determines how long it will last and how well it works. This is particularly important in wholesale markets, where dozens of springs may be sold at once, because customers prefer springs to ones that are unlikely to break or wear out too quickly. Lisheng understands the type of end has a lot to do with quality and durability for our springs, also this contributes to good work out value for money spent by final users

The ends of the springs C and D lie against each other, when in closed positions, but are not absolutely smooth. That means that when it’s used, the ends will often rub against internal parts in machines or tools. The spring can eventually wear out prematurely from this rubbing. But closed end springs are still pretty strong, and great for many uses, particularly when the surface area where the spring lies is not too fragile. They take less time to process, so they can be produced fast and sold cheap. This is great for buyers who need a lot of springs but don’t want to pay extra just for perfect flatness

The ends of ground end springs are machined flat after winding the closed coil. This gives very flat and smooth ends. This allows the spring to fit more snugly in tight spaces, and move around less or rub. This also makes for less wear and tear, so it gives the spring a longer life. Ground end springs produce a higher quality and more stable spring in machines with lots of part movement, or require exacting fits. But the additional grinding process makes these springs more expensive and slower to manufacture

Customers in wholesale markets are frequently forced to choose between cost and quality. Lisheng contributes a lot by keeping closed and ground end springs sustainable, advises on how long they last and perform. Ground end For application where free length consistency, durability & smooth action is important, ground end springs are the most suitable products. For lighter or more cost sensitive applications, closed end springs offer a good solution. Selecting the right end types to fit the needs without exceeding the budget or causing problems

Intimately knowing how end-type impacts durability and quality will empower customers in making smarter purchase decisions where buying in bulk is concerned. Lisheng has strong support and high standards, and the quality of every spring sold is guaranteed to meet customer requirements, whether a closed end or ground end spring. In this way, buyers get the most spring for their money and their projects

Table of Contents

- Compression Spring End Types: Closed and Ground

- Where to Turn for the Best Compression Springs with Closed vs. Ground Ends, For Bulk Purchase

- Popular Problems in the selection of Closed End and Ground end Compression Springs on Bulk Orders

- Where Closed End Compression Springs Outperform With Ground Ends Heavy Duty Application

- How End Type Affects Durability and Quality of Compression Springs in Wholesale Markets