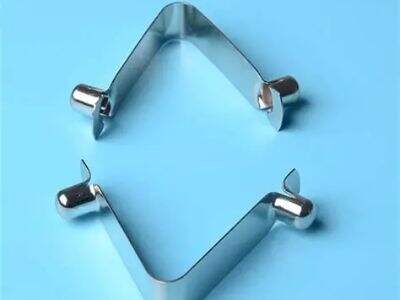

Material selection for a conductive V shaped flat spring is so critical. Such a spring isn’t just any piece of metal; it has to conduct electricity well, yet hold its shape even when pressed or stretched. If the material is flimsy or fails to conduct electricity well, the spring may eventually snap or fail. Lisheng knows good and long lasting springs because we make them! Materials with which these springs are made, either round or square wires, include: Music wire, stainless steel Type 302/304, hard drawn, stainless steel type 316. Other materials for your request Why choose us: Offer largest selection of stock springs. Available to serve small quantitiesObserving the highest quality Customization is our fuel Security for the business purchase Legal import licensing: Established in 2009 About ten years professional experience: Gold supplier at Alibaba. Should the wrong material be chosen, a spring can lose strength, or it might not have any conductive properties at all, meaning it could potentially wreak havoc in the machines where these springs are put to work. So using the right stuff to make these springs can be the difference in how well they work

Materials Selection of Reliable Conductive V Shape Flat Springs

Choosing the right material is more complicated than it sounds. You cannot use any metal because the spring must be able to repeatedly bend and yet still return to its original shape. It also has to transmit electric current without losing power or making excessive heat. One thing to consider is the material’s conductivity, how easily electricity can pass through it. And if the metal isn’t a good conductor of electricity, the spring won’t perform well. Another critical aspect is the strength and flexibility of the metal. Some metals will crack or snap after being bent a few times. That is not going to be good for springs that have a lot of motion. Copper, for instance, is extremely conductive but can be soft; it may wear out if used by itself. And sometimes you can mix metals or add finishes. Lisheng’s experience demonstrates that selecting materials with the right combination of strength and conductivity prolongs the life and improves performance of our springs. Temperature plays a role, too: many metals deform or lose conductivity as they heat up. Thus, having a guess where the spring will be used in an application can narrow down your choice of right metal by a large margin. We are always testing the different materials and designs until we find what matches the best. This consideration ensures that Lisheng's conductive V shaped flat springs' performance lasts for a long time

What Are the Best Materials of Conductive V Shaped Flat Springs For Wholesale Purchasers

Wholesale buyers want springs that last and work reliably. To the best of Lisheng’s knowledge, copper alloys are the most suitable materials for these springs. Copper is known for its electrical conductivity, and when combined with other metals like beryllium or nickel, it makes for something stronger and more durable. Consider beryllium copper, for example. Buyers also often opt for phosphor bronze as material of choice. It’s strong and not susceptible to corrosion, so it won’t rust or break down even in challenging situations. Sometimes stainless steel is employed, but mainly for springs that require extra strength and do not have to conduct electricity as efficiently. For its part, Lisheng recommends copper alloys as the best balance of flexibility, strength, and conductivity. We also ensure that the materials pass rigorous quality checks before they are released from our factory. Wholesale buyers trust us because they know the small-batch materials we choose have an impact on how well the springs perform. The proper materials for the springs can save money in the long run, because there’s not a lot of need to replace them, which is pretty significant for companies using countless numbers of tens or hundreds of thousands of these parts

Influence of the Material Property on Conductivity and Endurance of V-Shaped Flat Springs

When discussing V shaped flat springs that must be able to conduct electricity, selecting an appropriate material is of utmost importance. These springs are unique because not only do they need to be strong and flexible, but they also must allow an electric current to pass through them freely. If it’s not made of the right stuff, the spring may quit working too soon or won’t conduct electricity well enough

First, let’s think about conductivity. Conductivity measures how well a material can allow electricity to flow through it. And copper and silver are very good at that because their little parts, called electrons, can run around inside these lumps of stuff really easily. In the case of a conductive V shaped flat spring it is desirable to use highly conducting material so that an electrical signal or power can pass through without variation. If the material is poorly conductive, it causes the spring to be heated and wasted energy; This situation is for long-term use

Then there’s the material, which also factors into strength and flexibility. These springs must flex and snap back many times. The harder material, the statistics showed, is less likely to spring so far open that it becomes misshapen. If it is too rigid, becoming hard to bend. This makes the spring keep going for longer and work well over time

Another major part is resistance to corrosion. Springs frequently operate in situations with moisture or chemicals. If it is prone to rust or can be easily damaged, the spring will stop functioning and working sooner. Made of materials like stainless steel or coated metal, the spring is protected from rust and corrosion so it lasts longer

At Lisheng, we ensure that the materials we use have an ideal combination of conductivity, mechanical strength, flexibility and wear resistance. This thoughtful selection ensures our V shaped flat springs deliver good performance and ensures a long lifespan. It is a good material to work with so the spring will be able to do its job and not have any issues. So, the material properties really change both how good a spring it is at conducting electricity and also how useful that spring will be

Typical mistakes in selecting material when buying conductive V shaped flat springs

One mistake that most people do when purchasing conductive V shaped flat springs is choosing the material but not the right one. These errors can result in weak springs, low conductivity, or too early spring breakage. Understanding what to avoid makes it far easier for customers to purchase durable springs that work correctly

A frequent error is selecting material because it is cheap. At other times, lower-cost metals, think poor-quality steel or alloys, may seem all right, but they don’t transmit electricity for squat and can barely take a bend. This makes for springs that break and fail or cause electrical issues. At Lisheng, we will always tell the buyers to consider positive value instead of just price. Quality materials may be more expensive but cost less in the long run since they last and perform better

Another mistake is not taking into account how the spring will be utilized. Different environments need different materials. For instance, if the spring will be subjected to the outdoors or to a wet environment; it is better not to use materials that are prone to rust. Some purchasers select materials with no thought to corrosion resistance, which can cause rust and premature failure. Selecting materials with high corrosion resistance, such as some types of stainless steel or coated metals, is crucial

Buyers also can miss the importance of being able to move and grow. The spring may not function properly if the material is too rigid or too soft. It could tear or lose its form. If these properties are not checked properly the springs can be weak and inconsistent

Finally, some customers forget to verify the material meets industry standards. Standards also verify the material is tested to perform suitably for conductive springs. Absent this, buyers could receive springs that do not meet quality requirements

LiSheng is committed to helping customers avoid these mistakes and does this through the provision of expert guidance, along with quality material that tested at rigorous criteria. We want our customers to purchase the exact springs that will work best for their specific application. Preventing these common material mistakes saves time, money, and frustration ensuring the conductive v shaped flat springs perform perfectly

Advice for Wholesale Buyers on Material Requirements in Conductive V Shaped Flat Springs

V Shaped Flat Springs for conductor users and market In the case of a wholesale buyer, it plays a large part in selecting an appropriative conductive V shaped flat springs since they purchases products in bulk and delivers to many merchandisers. Material Standards are key for wholesale buyers to know in order to ensure the springs that they buy will be safe, dependable and a good product

Rules for what type of metals and materials can be used for springs are known as material standards. They also provide criteria for conductance, tensile strength, flexibility, and corrosion resistance tests. Once a spring meets these benchmarks, it has been scrupulously vetted and should work great under real-world conditions

For those who are in the wholesale business, being aware of these standards would avoid getting low quality springs that tend to fail early or may lead to electrical issues. If the material in a spring is not up to standard, that spring may not last for very long or could even prove perilous inside certain machines or devices

From Lisheng, you’ll get the springs that conform to stringent material standards. We’re using materials that have been tested to ensure they have good conductivity so electricity can flow without issue. We also test for strength and flexibility so the springs can bend multiple times without breaking. They are also tested for corrosion resistance in order to last even in harsh environments

If you are, sellers should give you certificates or test reports that show the materials meet these standards. That helps buyers trust in the quality and avoid any surprises after they Buy. It also aids buyers in explaining to customers that the springs they sell are of a superior quality and durability

The end, material standards are of the utmost importance to wholesale buyers. These V shaped flat springs that are conductive work and last well under pressure. Lisheng offers wholesale purchasers as much information and quality materials as it can. That way, buyers can have the confidence that they are selecting for the best springs so that their business is stronger and their customers happier

Table of Contents

- Materials Selection of Reliable Conductive V Shape Flat Springs

- What Are the Best Materials of Conductive V Shaped Flat Springs For Wholesale Purchasers

- Influence of the Material Property on Conductivity and Endurance of V-Shaped Flat Springs

- Typical mistakes in selecting material when buying conductive V shaped flat springs

- Advice for Wholesale Buyers on Material Requirements in Conductive V Shaped Flat Springs