When things are squishy or stretchy, pressure springs to the rescue! Special springs are very useful in machines, they can absorb and distribute forces. There stainless compression springs are other types of pressure springs, such as coil springs and leaf springs, which could be applied in plenty of projects. But how do pressure springs operate, and how do you go about selecting the correct one for your project? Pressure springs are kind of tiny assistance in tools and machines. They can be squeezed or stretched to store energy that can then be released when needed. Like for example when you jump in a pogo stick the pressure spring gets squished and then it pushes back to make you jump high, yo!

In a car, pressure springs will be found in the suspension to absorb road bumps and shocks. Without them, the journey would be a very bumpy and uncomfortable trip. So, pressure springs are such secret agents working unnoticed behind the scenes to facilitate a smooth operation Pressure Springs Pressure springs operate according to elasticity and Hooke´s Law. If helical compression spring pressure is applied to a pressure spring, for example, it deforms. But when the force is removed, the spring returns to its original form, releasing the energy it stored.

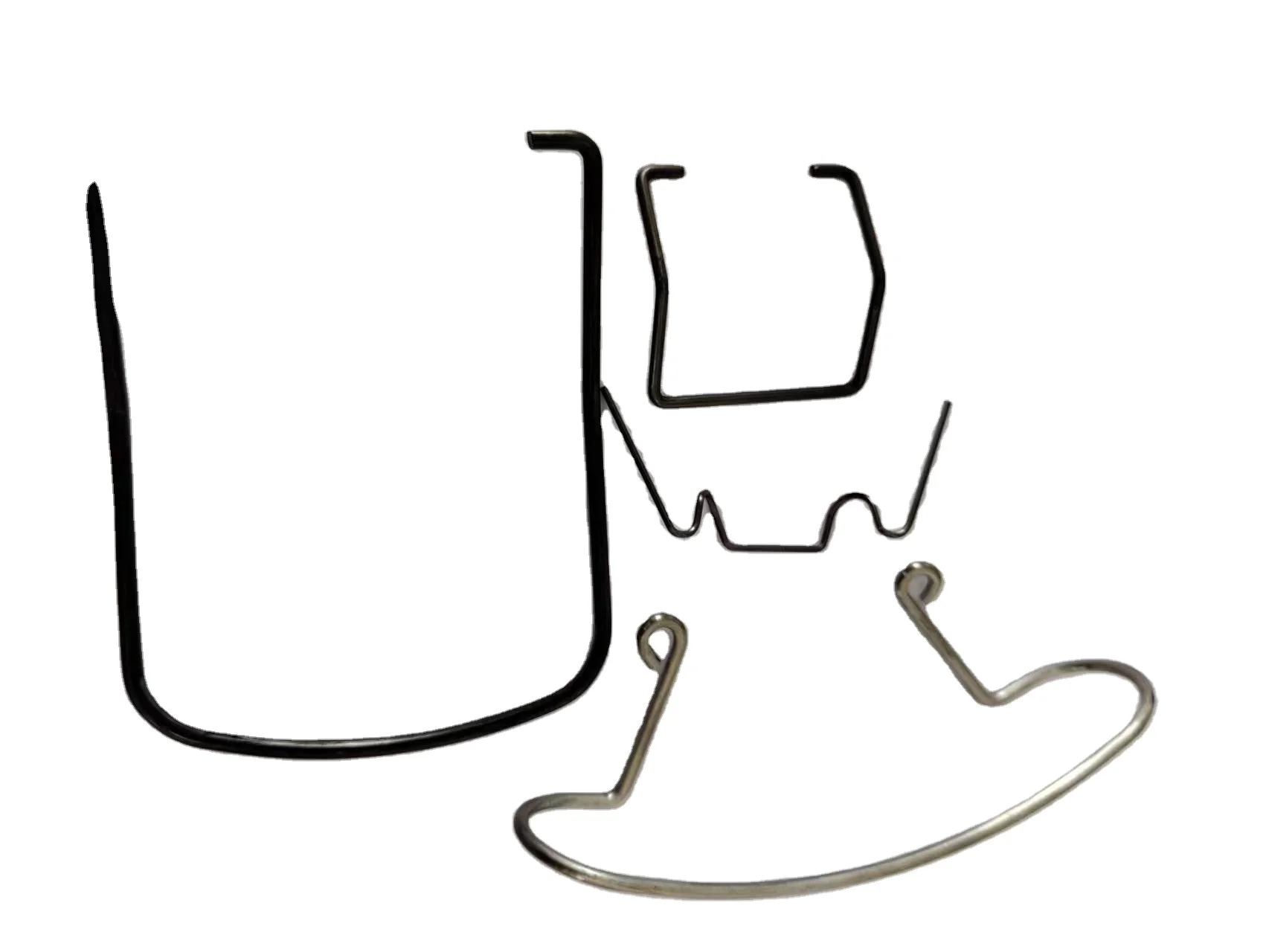

How it’s made, its materials, and its size and shape determine how it will behave under various forces. When it engineers come up with a size for a pressure spring, they helical coil spring use math and science to figure out the right size to make sure the pressure spring works really well in a machine.

When selecting a pressure spring for your project, consider the amount of force it must take, the room it will have to occupy, and how long it will need to last. Also, think about where stainless steel compression springs it will be used — such as if is going to be subjected to heat or harmful substances.

Speaking with a pro can get you the right pressure spring for your purposes. They will be able to advise on what spring is required and give repeat if required. We have over 2,000 different sizes and types of pressure springs available for you to select from; choose the compression springs best one, and your machines will run smoothly and produce the best results.

The company has advanced spring design, manufacturing and testing technology, the use of high-precision equipment and automated production lines, to ensure product performance stability, reliable quality, strict selection of high-quality raw materials, to ensure that the spring has high strength, high elasticity and excellent fatigue resistance, extend the service life. Through the IATF16949 and other six kinds of international quality system certification, products through strict testing, in line with industry standards, stable and reliable performance.

The company has an experienced research and development team, focusing on material science, mechanical properties and manufacturing process innovation, can provide customers with high performance, high reliability spring products. Secondly, the company adopts advanced simulation design software and test equipment to optimize the spring structure through simulation analysis and experimental verification, ensuring that the product reaches the industry-leading level in strength, elasticity and fatigue resistance. In addition, the company focuses on customized research and development, and can quickly design and produce spring solutions for specific conditions according to customer needs.

Our spring products have a number of significant advantages. First, they have high elasticity and durability to ensure that they can maintain stable performance under frequent compression and stretching, and extend service life. Secondly, the spring design is flexible, and the shape, size and material can be customized according to different needs, which is widely used in automotive, machinery, home and other fields. In addition, the spring has good fatigue resistance and can withstand long-term cyclic load without damage. Its high-precision manufacturing process ensures product consistency and reliability, meeting stringent industry standards.

The company is committed to providing customers with comprehensive and efficient support. First of all, the company has established a professional after-sales team, which can quickly respond to customer needs, provide technical advice, problem diagnosis and solutions to ensure that customer problems are handled in a timely manner. Secondly, the company provides perfect warranty policies and regular maintenance services to extend product life and reduce customer operating costs. At the same time, the company pays attention to customer feedback and continuously optimizes products and services to ensure customer satisfaction.

Copyright © Ningbo Jiangbei Lisheng Spring Co., Ltd. All Rights Reserved | Privacy Policy | Blog