That's why spring manufacturers in china is so important in instrument making. It produces heavenly sounds when it is plucked or struck. It is also known as piano wire, because it was once used to make piano strings. In addition to pianos, music wire is also used in guitar strings, violin strings, harp strings, and many other types of instruments. Well, time to learn more about music wire and its role in creating that beautiful music we love.

Music wire is a kind of wire which consists of high-carbon steel or strong steel. This steel is capable of having very high tensile strength, which is why it is used to make strings for musical instruments. Music wire comes in various thicknesses, or gauges, that affect the sound it produces. Thicker wire produces lower notes, while thinner wire produces higher notes.

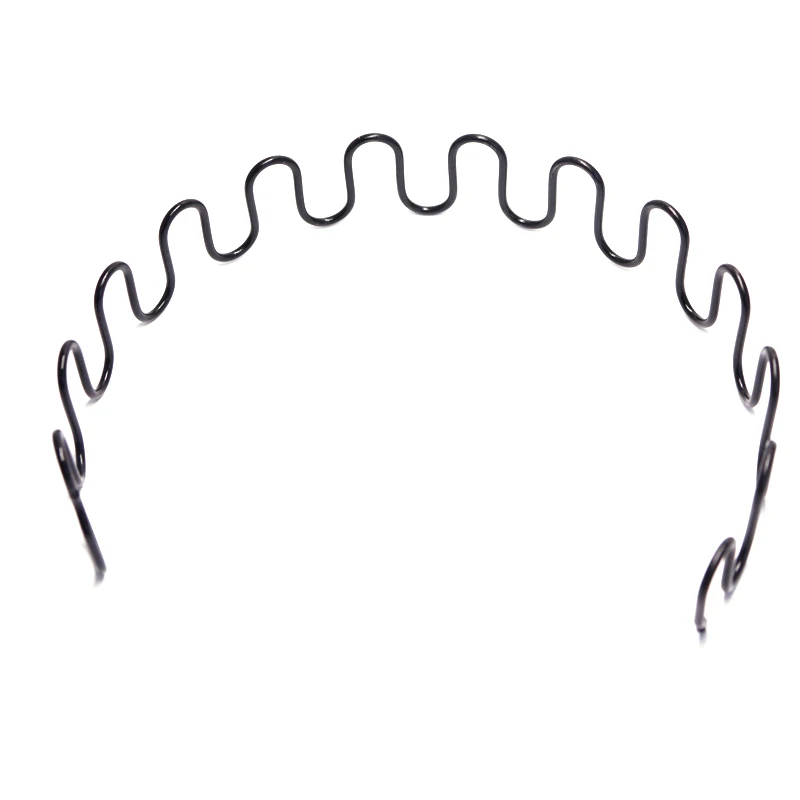

After all, that isn’t zigzag spring, so if you play an instrument with music wire strings, here’s some advice on keeping your instrument soundin’ good. So a tip is always check the gauge of your strings and make sure that you are tuning them properly Tuning your instrument you can use a tuner, or a piano کمک دیگر If your instrument is kept in a consistent temperature and humidity environment, it can also help. This prevents the strings from stretching or shrinking, which can affect the sound.

Music wire isn't only used for creating strings. It is also found in other parts of musical instruments, such as springs and mechanisms. For example, in a piano, the keys are attached to hammers that strike the strings when pressed. The hammers are connected to the keys via springs, constructed of music wire. The tension and flexibility of the wire are really critical to how the hammers move and produce sound.

Music wire has special features, which is why it makes such beautiful sounds. A string vibrates when you pluck or strike it at a certain frequency. These vibrations go into the air as sound waves which we hear as music. The music wire is made of high-carbon steel, which can vibrate freely to create a clear, rich tone. The wire thickness and tension create different sounds, too.

For example, the thickness and tension of music wire radically alters the instrument's sound. Thicker wire produces deeper, richer tones; thinner wire, brighter, higher tones, for instance. The tension of the wire can also consider how loud the sound is and how long it lasts. Nonlinear guitars and other projects Musicians and instrument makers select the appropriate music wire; they have to select the right type for the voice of their instruments.

The company has an experienced research and development team, focusing on material science, mechanical properties and manufacturing process innovation, can provide customers with high performance, high reliability spring products. Secondly, the company adopts advanced simulation design software and test equipment to optimize the spring structure through simulation analysis and experimental verification, ensuring that the product reaches the industry-leading level in strength, elasticity and fatigue resistance. In addition, the company focuses on customized research and development, and can quickly design and produce spring solutions for specific conditions according to customer needs.

The company is committed to providing customers with comprehensive and efficient support. First of all, the company has established a professional after-sales team, which can quickly respond to customer needs, provide technical advice, problem diagnosis and solutions to ensure that customer problems are handled in a timely manner. Secondly, the company provides perfect warranty policies and regular maintenance services to extend product life and reduce customer operating costs. At the same time, the company pays attention to customer feedback and continuously optimizes products and services to ensure customer satisfaction.

Our spring products have a number of significant advantages. First, they have high elasticity and durability to ensure that they can maintain stable performance under frequent compression and stretching, and extend service life. Secondly, the spring design is flexible, and the shape, size and material can be customized according to different needs, which is widely used in automotive, machinery, home and other fields. In addition, the spring has good fatigue resistance and can withstand long-term cyclic load without damage. Its high-precision manufacturing process ensures product consistency and reliability, meeting stringent industry standards.

The company has advanced spring design, manufacturing and testing technology, the use of high-precision equipment and automated production lines, to ensure product performance stability, reliable quality, strict selection of high-quality raw materials, to ensure that the spring has high strength, high elasticity and excellent fatigue resistance, extend the service life. Through the IATF16949 and other six kinds of international quality system certification, products through strict testing, in line with industry standards, stable and reliable performance.

Copyright © Ningbo Jiangbei Lisheng Spring Co., Ltd. All Rights Reserved | Privacy Policy | Blog