Determining torsion springs long life

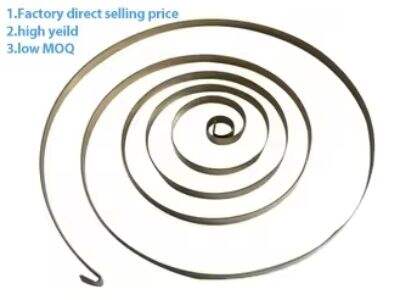

There are a lot of people who do not appreciate how crucial torsion springs are. They are similar to little coils that up and produce powers to make things run. Our torsion springs, just as we field a finite lifetime of our own. In other words these things are designed to only last so long before they start to deteriorate and fail. Ensuring the lifespan of Torsion Spring is something essential to lessen the risks the machines are going through.

Red Flags for Potential Failure

Old torsion springs will begin to display these signs in a very dangerous way. The machine makes noise during operation, the device jerks or even deforms in other ways that could point towards wear and tear on the spring. These signs can be indicators of a spring on the very brink of failing, and it's vital to act before that moment arrives. When you can find a future failure, that means it will save you from an accident and your machines price by maintaining them working properly.

How to extend the lifespan of torsion springs?

Fortunately, there are some little tips and tricks that you can use to make your torsion springs live longer than usual. A small tip is to ensure that the spring is fully greased. This can help reduce third shock which will in turn lower friction and wear to allow the spring to move more freely. Just don't overload the spring! If a spring remains under too much pressure at all times, it may wear more quickly. If you follow these tips and pay attention to your big torsion springs, you are going to be able to extend their life and have the ability to keep machines running great.

Why Torsion Springs Malfunction?

Here are some common reasons that cause the torsion springs to fail. One of the most usual causes. If a spring is exposed to water, the spring can begin to rust and corrode. Too much tension is not good for the spring as it will be under constant pressure and deteriorate. Knowing and understanding these widespread culprits is key in avoiding them, and maintaining your machines functionality.

How to maintain and inspect torsion springs

Preventative maintenance and inspection of your torsion springs is crucial in order to prevent failures and accidents. A regular interval is one common step that should be maintained to detect any wear or defect on the spring. This could be looking for rust and corrosion or other signs of visible as well as functional damage. Some others lube the heck out of that spring back there. It can help to reduce friction and also bonding and prolong spring life. With these springs, you can take care of your heavy duty torsion springs to work in the right way and prevent accidents.