Compression and die springs are common mechanical components that are used in various types of machinery and equipment. They absorb shock, store energy, and provide the force between two surfaces. Knowing something about these springs and how to appropriately order the right one for your purposes is very important for the maintenance and operation.

Compression springs are open-coil helical springs that offers resistance to a compressive force applied axially. They are used with a slipping or separating motion between the leaves when this plane movement is required, as in machine tools, presses, and motor vehicles to take up slack and minimize the effect of shock. Die springs in contrast are an industrial model, used for heavy load and heavy pressure applications. They are predominantly used for stamping and shaping.

When selecting a compression spring for a specific application, it is necessary to take many factors into account, such as the load level, working conditions, and available space. Lisheng spring has a professional team who can provide the good service from design, developing, material choosing,manufacturing and packing. Lisheng's most popular product is the different kinds of springs, including compression spring, extension spring, torsion spring, and spiral spring. The following is how you can choose the right compression spring for your application for it to perform effectively and last. 1.

There are various advantages in using die springs in the production. They have high bearing capacity, long service life, good anti-seizure property, good brightness. Die springs makes the use of die springs in die stamping & forming in manufacturing for consistent results. Lisheng Die spring uses high-quality materials and performs good quality control, which ensures its reliability and durability.

Compression spring upkeep is necessary to keep these springs working well and lasting long. If the condition of the springs is checked periodically for wear, rust or fatigue that may lead to failure, such failure or breakdown is also avoidable. If the compression spring is malfunctioning, you can troubleshoot by verifying it’s properly aligned, lubricated and installed.

Technological developments have brought improvements in the compression and die spring design. Modern materials and production methods have improved springs in terms of durability, weight, and performance. LiSheng is dedicating to keeping pace with the times and developing new springs to meet our customers’ requirements.

The company is committed to providing customers with comprehensive and efficient support. First of all, the company has established a professional after-sales team, which can quickly respond to customer needs, provide technical advice, problem diagnosis and solutions to ensure that customer problems are handled in a timely manner. Secondly, the company provides perfect warranty policies and regular maintenance services to extend product life and reduce customer operating costs. At the same time, the company pays attention to customer feedback and continuously optimizes products and services to ensure customer satisfaction.

Our spring products have a number of significant advantages. First, they have high elasticity and durability to ensure that they can maintain stable performance under frequent compression and stretching, and extend service life. Secondly, the spring design is flexible, and the shape, size and material can be customized according to different needs, which is widely used in automotive, machinery, home and other fields. In addition, the spring has good fatigue resistance and can withstand long-term cyclic load without damage. Its high-precision manufacturing process ensures product consistency and reliability, meeting stringent industry standards.

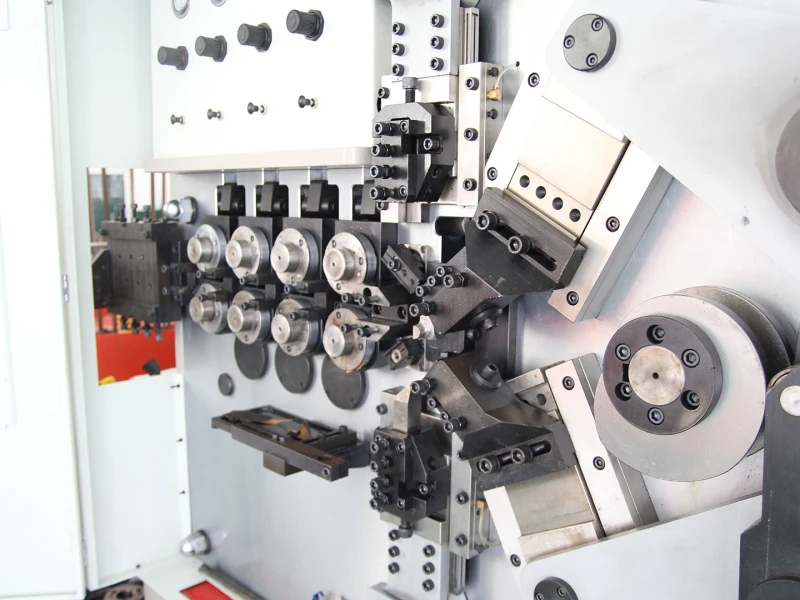

The company has advanced spring design, manufacturing and testing technology, the use of high-precision equipment and automated production lines, to ensure product performance stability, reliable quality, strict selection of high-quality raw materials, to ensure that the spring has high strength, high elasticity and excellent fatigue resistance, extend the service life. Through the IATF16949 and other six kinds of international quality system certification, products through strict testing, in line with industry standards, stable and reliable performance.

The company has an experienced research and development team, focusing on material science, mechanical properties and manufacturing process innovation, can provide customers with high performance, high reliability spring products. Secondly, the company adopts advanced simulation design software and test equipment to optimize the spring structure through simulation analysis and experimental verification, ensuring that the product reaches the industry-leading level in strength, elasticity and fatigue resistance. In addition, the company focuses on customized research and development, and can quickly design and produce spring solutions for specific conditions according to customer needs.

Copyright © Ningbo Jiangbei Lisheng Spring Co., Ltd. All Rights Reserved | Privacy Policy | Blog